Thorough analysis of the actual structural integrity of your cranes can help you make significant savings when your OEM conditions state replacement is the only option.

Benefits

- Provided a cost effective solution

- Engineered solution which complied with legislative requirements

- No crane and operational down time

- Work scope completed ahead of time.

Challenge

Following a NDT inspection on the three pedestal cranes on board the jack up rig, it was found that all three booms had surface corrosion covering over 50% of their total surface areas.

A criterion set by the crane manufacturer states that if surface corrosion exceeds 50% of the total surface area of the boom, replacement is required and as a result, all three booms where condemned by the manufacturer with a replacement cost totalling $2.25 million dollars. This criterion does not take into account the wall thickness loss due to the corrosion.

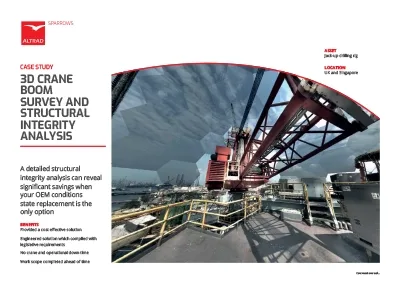

Due to the high replacement costs the customer wanted a second opinion and contracted Altrad Sparrows to perform a survey on each of the three cranes using 3D laser scanning and rope access trained surveyors. This scan would then allow us to perform a structural analysis and determine what effect the corrosion was having on the structural integrity of the booms. The aim of the study was to confirm if the corroded crane booms were still compliant with relevant design codes and whether or not remedial repair work would suffice.

Solution

- We created a 3D Finite Element Analysis (FEA) model of each of the three crane booms based on the available information and the 3D scan. Even though the cranes were the same make and model, all three booms were configured differently. The booms where analysed in accordance with API 2C in the un-corroded condition in order to obtain baseline member utilisations for comparison

- The boom models were then modified to simulate all relevant corrosion on each of the crane booms and analysed using the same design loads

- The highest utilised members of each crane boom was then compared against their respective un-corroded utilisations along with the utilisations of each corroded member and the elements surrounding the corroded members. This formed a clear picture of how the corrosion affected the structural integrity of each of the three booms

- In this case the corrosion had no major effect on the structural integrity of any of the three crane booms. The utilisation increases were minimal and all corroded members utilisations remained below 100% when measured against the requirements of API 2C. Therefore, all three crane booms where deemed suitable to continue service at full capacity

- The cost of doing this analysis was significantly lower than the replacement costs for all three cranes

- Should any of the crane booms have failed the analysis due to over utilisation, Altrad Sparrows could issue the customer with de-rated load curves based on the current state of the crane booms along with remedial local repair options to take to bring the boom back to its full safe working load.

Summary

- Survey of inaccessible crane structures using 3D laser scanning and rope access surveyors

- Finite Element Analysis (FEA)

- Remedial recommendations

- Technical support

- Project management.